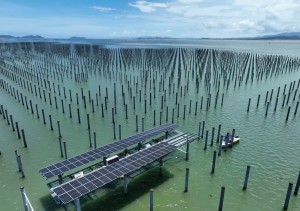

Fujian Province’s first offshore photovoltaic project – Dongshan Xingchen 180 MW offshore photovoltaic power station project (hereinafter referred to as “Dongshan Offshore photovoltaic Project”) full speed up the construction. Until June 19, 2024, the contractor has completed a total of 31,698 pipe pile sinking operations, completion rate of 94%; The installation of K-type metal supports, photovoltaic support system and photovoltaic panels began. The pile foundation construction of the land booster station has been completed. The installed capacity of the project is 180 MW, supporting the construction of a 110 kV onshore booster station and the construction of 18 MW /36 MWH energy storage system, which can provide an average of 300 million KWH of clean electricity and save 90,200 tons of standard coal every year after completion.

Dongshan Offshore photovoltaic project is located in Xingchen Town, Dongshan County, Zhangzhou City, Fujian Province, built on the sea surface of the beach, greatly affected by the tide, the average sunshine time of many years is 2204 hours, solar energy resources are rich.The annual average wind speed of 5.2 meters per second, the maximum wind speed can reach 48 meters per second, belongs to the typhoon-resistant tidal zone offshore photovoltaic project.

In order to cope with the influence of high wind speed and tide and other factors, the project innovatively applied the domestic first multi-pile + diagonal brace integral, applied Typhoon-resistant solar racking structure, and implemented the installation through the development of new construction equipment.

Unlike onshore PV, the primary consideration for offshore PV projects is anti-corrosion. Learning from the experience of offshore wind power anti-corrosion, K-type metal support, steel pipe piles are using Marine anti-corrosion system, Solar Mounting Bracket, component frame, inverter and box transformer material equipment are using high anti-corrosion standards. The bolts installed are special anti-corrosion bolts, and special attention should be paid to the operation, so that the anti-corrosion layer cannot be damaged a little.

Post time: Jul-09-2024